-

- Some services are not accessible on a smartphone.

- Sign In

- My Account

- My Cart

- Customer Service

- Bindery Parts & Equipment | Finishing Parts Equipment | Bindery Supply

- >TAKK Static Control Applications for Converting

Static Eliminators for Converting

TAKK static eliminators ensure uniform dispersion of ionized air across various operations such as slitting, sheeting, unwinding, rewinding, laminating, and coating. By doing so, they effectively eradicate the static electricity responsible for frequent shocks to personnel and prevent static-related issues like jamming, material clinging, and sticking during the processing of papers and films commonly used in conversion and packaging processes.

Bag Wicket

Bag Wicket

Excessive static charges can lead to bags sticking together or repelling when stacked, causing inefficient stacking, reducing production output, and raising the number of rejected items. To address this issue, installing static eliminators at the entry point of the bags, while on the wickets, and within the stack area ensures effective neutralization of individual bags and the collated stack, facilitating proper stacking alignment.

Recommended Solutions:

|  |

| 400T Ionizing Bar | IonStorm XR2 |

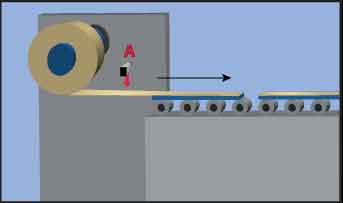

Slitting

While unwinding the web from the roll and separating the material, a static charge is generated. This charge intensifies as the web traverses rollers and during material slitting. When the material begins rewinding, this static charge can lead to layers repelling each other, compromising roll quality.

To counter this issue, the installation of a static eliminator before rewinding is essential. This device will neutralize the charge, preventing contamination and ensuring high-quality rolls.

Recommended Solutions:

|  | |

| IonStorm XR2 | Curtain-Air Ionizer | Vortex Ionizer Blower |

Sheeting

In high-speed applications like sheeting, static is produced due to rapid movement, friction, and material separation. During the sheeting process, the sheets are drawn towards the machinery and repel each other when stacked.

By placing a static eliminator above and immediately after the sheeting operation, the static charge can be neutralized. This action will result in better stacking, and reduced instances of jams and downtime, ultimately enhancing productivity.

Recommended Solution:

|

| 400T Ionizing Bar |

Winding

While unwinding the material from the roll during the winding process, a static charge is generated as the web separates. This static electricity tends to attract airborne dust and contaminants, leading to rejected products, increased waste, and potential shocks for operators.

To address this issue in both unwinding and rewinding scenarios, the installation of a static eliminator on the roll's surface effectively neutralizes the charge. This proactive measure helps prevent contamination and operator shocks, ensuring a smoother and more efficient operation.

Recommended Solutions:

|  |  |

| IonStorm XR2 | Curtain-Air Ionizer | Vortex Ionizer Blower |

Applying Protective Sheets to Metal/Plastic

Applying Protective Sheets to Metal/Plastic

Manufacturers and processors of steel, glass, or plastic sheets often need to apply protective liners or interleaf sheets to finished goods before packaging for shipment. Traditional methods like adhesives and strapping are costly and time-consuming, potentially disrupting the creation of uniform stacks. Non-contact electrostatic charging offers a swift and non-abrasive alternative, proving efficient, rapid, and reliable without requiring additional consumables.

Recommended Solution:

|

| IONFIX Static Generator System |